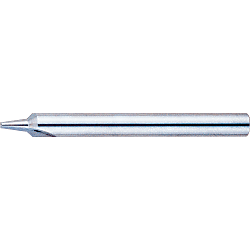

Carbide Straight Blade Tapered End Mill, 2-Flute, with Chamfering Blade

-Kegelförmige Halsabschrägungsklinge, die stark zu einer konischen Bearbeitung beiträgt, die eine Prozessreduzierung erfordert

Teilenummer

Hier finden Sie die Teilenummern

zu dem gesuchten Artikel

| Teilenummer | Mindestbestellmenge | Mengenrabatt | Shank Diameter d (mm) | Overall Length L (mm) | #2 | #3 | #4 | #5 | #6 | 1D | 2D | 3D | 4D | F | T | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 7 Arbeitstage | 4 | 50 | 0.5 ~ 2.5 | 0 ~ 30 | 0 ~ 59 | 0.5 ~ 10 | 0.5 ~ 1.7 | - | - | - | - | F | T | ||

| 1 | 7 Arbeitstage | 4 | 50 | 0.5 ~ 2.5 | 0 ~ 30 | 0 ~ 59 | - | 0.5 ~ 1.7 | 1 | 2 | 3 | 4 | F | T | ||

| 1 | 9 Arbeitstage | 6 | 60 | 0.5 ~ 4.5 | 0 ~ 30 | 0 ~ 59 | 0.5 ~ 18 | 0.5 ~ 2.7 | - | - | - | - | F | T | ||

| 1 | 9 Arbeitstage | 6 | 60 | 0.5 ~ 4.5 | 0 ~ 30 | 0 ~ 59 | - | 0.5 ~ 2.7 | 1 | 2 | 3 | 4 | F | T | ||

| 1 | 9 Arbeitstage | 8 | 60 | 0.5 ~ 6.5 | 0 ~ 30 | 0 ~ 59 | 0.5 ~ 26 | 0.5 ~ 3.7 | - | - | - | - | F | T | ||

| 1 | 9 Arbeitstage | 8 | 60 | 0.5 ~ 6.5 | 0 ~ 30 | 0 ~ 59 | - | 0.5 ~ 3.7 | 1 | 2 | 3 | 4 | F | T | ||

| 1 | 9 Arbeitstage | 10 | 80 | 0.5 ~ 8.5 | 0 ~ 30 | 0 ~ 59 | 0.5 ~ 34 | 0.5 ~ 4.7 | - | - | - | - | F | T | ||

| 1 | 9 Arbeitstage | 10 | 80 | 0.5 ~ 8.5 | 0 ~ 30 | 0 ~ 59 | - | 0.5 ~ 4.7 | 1 | 2 | 3 | 4 | F | T | ||

| 1 | 9 Arbeitstage | 12 | 80 | 0.5 ~ 10.5 | 0 ~ 30 | 0 ~ 59 | 0.5 ~ 36 | 0.5 ~ 5.7 | - | - | - | - | F | T | ||

| 1 | 9 Arbeitstage | 12 | 80 | 0.5 ~ 10.5 | 0 ~ 30 | 0 ~ 59 | - | 0.5 ~ 5.7 | 1 | 2 | 3 | 4 | F | T | ||

| 1 | 9 Arbeitstage | 16 | 100 | 0.5 ~ 14.5 | 0 ~ 30 | 0 ~ 59 | 0.5 ~ 48 | 0.5 ~ 7.7 | - | - | - | - | F | T | ||

| 1 | 9 Arbeitstage | 16 | 100 | 0.5 ~ 14.5 | 0 ~ 30 | 0 ~ 59 | - | 0.5 ~ 7.7 | 1 | 2 | 3 | 4 | F | T |

Loading...

Spezifikationen

[ ! ]Even if dimensions within the specifiable range are specified, depending on the combination of each dimension some products may be unable to be manufactured.

| Model Number | Flute Diameter D 0.01 mm Increment Designation | Single Angle θ ° - ' 1' Increment Designation | Flute Length * ℓ 0.5 mm Increment Designation | Chamfer Blade Width * CM 0.1 mm Increment Designation | Bottom Blade Shape (Selection) | Blade Portion ℓ1 | Overall Length L | Standard Unit Price 1 ~ 2 Pieces | ||

| Shank Diameter d | ||||||||||

| Specified Range | ℓ max. | |||||||||

| STCMEM | 4 | 0.50 ~2.50 | 0°15' ~ 30°0' | (1) 0.5 ≤ ℓ ≤ D x 4 and (2) ℓ ≤ ℓ max. (refer to table on right) and  | 10.0 | 0.5 ≤ CM ≤ * | T (Dished) F (Flat) Bottom Blade Shape P.608 | ℓ1 = ℓ + CM | 50 | |

| 6 | 0.50 ~4.50 | 18.0 | 60 | |||||||

| 8 | 0.50 ~6.50 | 26.0 | 60 | |||||||

| 10 | 0.50 ~8.50 | 34.0 | 80 | |||||||

| 12 | 0.50 ~ 10.50 | 36.0 | 80 | |||||||

| 16 | 0.50 ~ 14.50 | 48.0 | 100 | |||||||

* Depending on the size of ℓ, the entire gradient angle may be blade length. Maximum Chamfer Blade Width CM (max) = (d - D - tanθ x ℓ x 2) / 2

Optionen

Grundlegende Informationen

| Material | Ultrafine Particulate Carbide | Cutting Part ℓ1(mm) | ℓ1 = ℓ + CM |

|---|

Konfigurieren

Basiseigenschaften

-

Shank Diameter d(mm)

- 4

- 6

- 8

- 10

- 12

- 16

-

Overall Length L(mm)

-

#2

-

#3

-

#4

-

#5

-

#6

-

1D

-

2D

-

3D

-

4D

-

F

-

T

-

Ausführung

- STCMEM

Filtern nach vsl. Lieferzeit

-

- Alle Produkte

- 7 Tage oder weniger

- 9 Tage oder weniger

Optionale Eigenschaften

- Die Spezifikationen und Maße einiger Teile sind evtl. nicht vollständig enthalten. Genaue Details siehe Herstellerkataloge .