Parallel-Pneumatik-Greifer mit weiter Öffnung, Serie MHL2 (Teilenummern - CAD Download)

(i)Hinweis

- Refer to the catalog for details on product specifications.

- Product images may be representative. Refer to the manufacturer's catalog for details.

Teilenummer

Hier finden Sie die Teilenummern

zu dem gesuchten Artikel

MHL2-16D-M9P

Parallel Style Wide Opening Air Gripper MHL2 Series Specifications

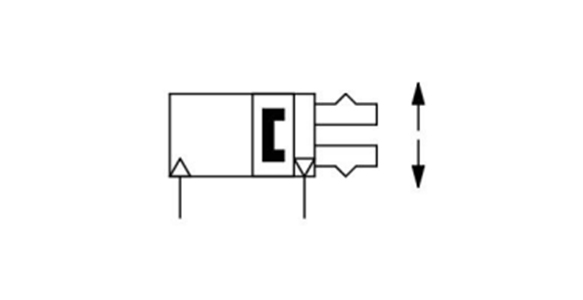

Double acting, internal grip JIS symbol

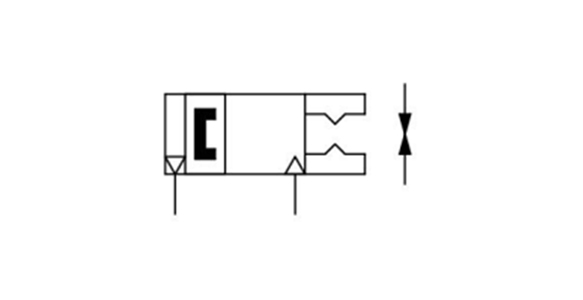

Double acting, external grip JIS symbol

| Bore size (mm) | 10 | 16 | 20 | 25 | 32 | 40 |

|---|---|---|---|---|---|---|

| Fluid | Air | |||||

| Action | Double acting | |||||

| Operating pressure (MPa) | 0.15 to 0.6 | 0.1 to 0.6 | ||||

| Ambient and fluid temperature | -10 to +60°C | |||||

| Repeatability | ±0.1 | |||||

| Lubrication | Non-lube | |||||

| Effective gripping force (N) at 0.5 MPa * | 14 | 45 | 74 | 131 | 228 | 396 |

*Gripping position is 40 mm for bore size 10 mm, 16 mm, 20 mm, 25 mm, and 80 mm for bore size 32 mm, 40 m.

Model/Stroke

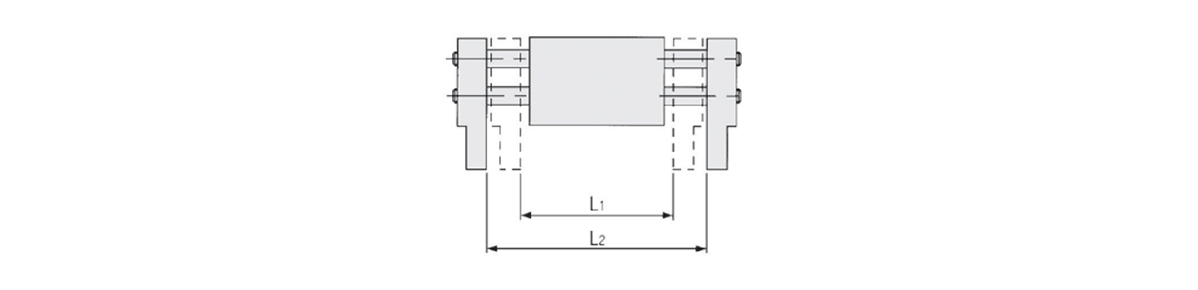

Opening/closing stroke

| Model | Bore size mm | Maximum operating frequency c.p.m | Opening/closing stroke (mm) (L2-L1) | Width at closing (mm) (L1) | Width at opening (mm) (L2) | Weight g |

|---|---|---|---|---|---|---|

| MHL2-10D | 10 | 60 | 20 | 56 | 76 | 280 |

| MHL2-10D1 | 40 | 40 | 78 | 118 | 345 | |

| MHL2-10D2 | 60 | 96 | 156 | 425 | ||

| MHL2-16D | 16 | 60 | 30 | 68 | 98 | 585 |

| MHL2-16D1 | 40 | 60 | 110 | 170 | 795 | |

| MHL2-16D2 | 80 | 130 | 210 | 935 | ||

| MHL2-20D | 20 | 60 | 40 | 82 | 122 | 1,025 |

| MHL2-20D1 | 40 | 80 | 142 | 222 | 1,495 | |

| MHL2-20D2 | 100 | 162 | 262 | 1,690 | ||

| MHL2-25D | 25 | 60 | 50 | 100 | 150 | 1,690 |

| MHL2-25D1 | 40 | 100 | 182 | 282 | 2,560 | |

| MHL2-25D2 | 120 | 200 | 320 | 2,775 | ||

| MHL2-32D | 32 | 30 | 70 | 150 | 220 | 2,905 |

| MHL2-32D1 | 20 | 120 | 198 | 318 | 3,820 | |

| MHL2-32D2 | 160 | 242 | 402 | 4,655 | ||

| MHL2-40D | 40 | 30 | 100 | 188 | 288 | 5,270 |

| MHL2-40D1 | 20 | 160 | 246 | 406 | 6,830 | |

| MHL2-40D2 | 200 | 286 | 486 | 7,905 |

*The open and close time spans represent the valve when the exterior of the workpiece is being held.

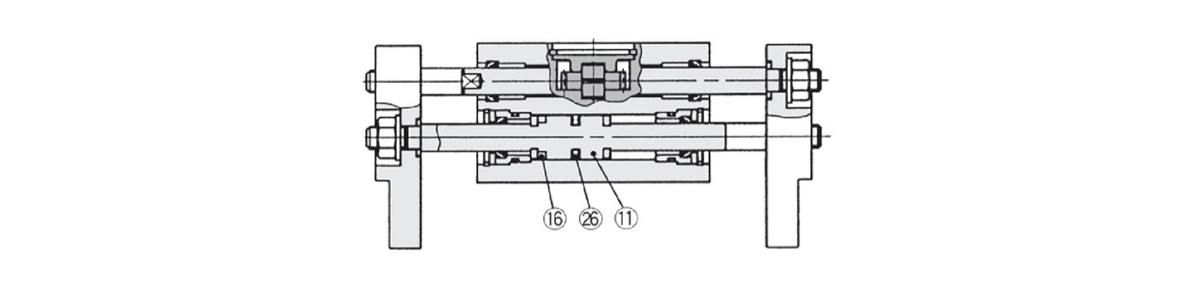

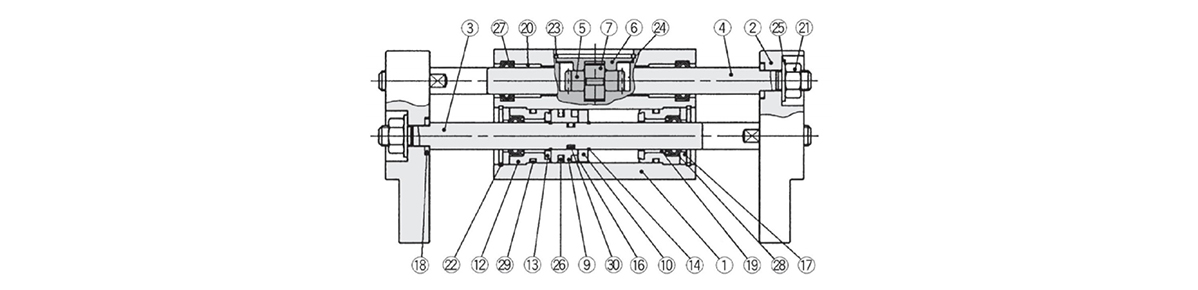

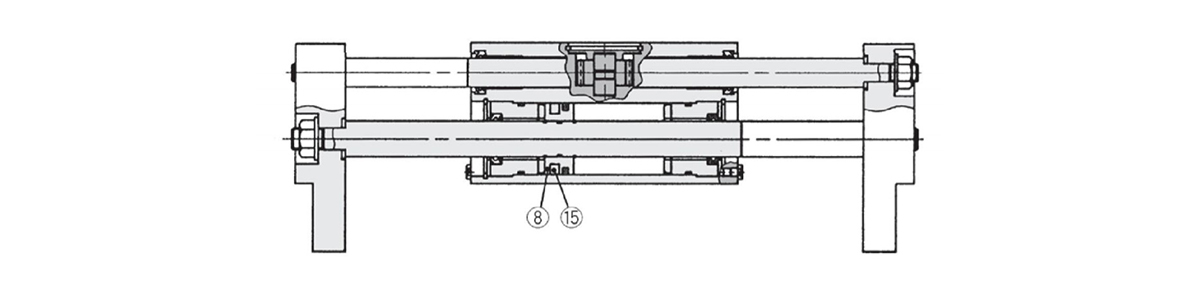

Structure drawing

ø10 (bore size 10 mm) structure drawing

ø16 to 25 (bore size 16 to 25 mm) structure drawing

ø32 (bore size 32 mm), ø40 (bore size 40 mm) structure drawing

| No. | Description | Material | Note |

|---|---|---|---|

| 1 | Body | Aluminum alloy | Hard anodized |

| 2 | Finger | Aluminum alloy | Hard anodized |

| 3 | Piston rod | Stainless steel | - |

| 4 | Rack | Stainless steel | - |

| 5 | Pinion | Carbon steel | Nitriding |

| 6 | Pinion cover | Carbon steel | Electroless nickel plated |

| 7 | Pinion axis | Stainless steel | Nitriding |

| 8 | Piston | Brass | - |

| 9 | Piston A | Brass | - |

| 10 | Piston B | Brass | - |

| 11 | Piston A | Stainless steel | - |

| 12 | Rod cover | Aluminum alloy | Chromate treated |

| 13 | Bumper | Urethane rubber | - |

| 14 | Clip | Stainless steel spring wire | - |

| 15 | Rubber magnet | Synthetic rubber | - |

| 16 | Magnet | - | Nickel plated |

| 17 | Rod seal cover B | Cold rolled steel plate | Electroless nickel plated |

| 18 | Washer | Stainless steel | Nitriding |

| 19 | Bearing | Oil-containing polyacetal with back metal | - |

| 20 | Bearing | Oil-containing polyacetal with back metal | - |

| 21 | U nut | Carbon steel | Zinc chromated |

| 22 | R-shaped retaining ring | Carbon steel | Phosphate coated |

| 23 | Type C retaining ring | Carbon steel | Phosphate coated |

| 24 | Wave washer | Spring steel | Phosphate coated |

| 25 | Conical spring washer | Carbon steel | Nickel plated |

| 26 | Piston seal | NBR | - |

| 27 | Rod seal | NBR | - |

| 28 | Rod seal | NBR | - |

| 29 | Gasket | NBR | - |

| 30 | Gasket | NBR | - |

External dimensional drawing

(Unit: mm)

MHL2-10D□ dimensional drawing

(Unit: mm)

MHL2-10D□ dimensional drawing 2

(Unit: mm)

MHL2-10D□ K cross view (fingers closed) dimensional drawing

(Unit: mm)

Auto switch mounting groove (enlarged view) dimensional drawing

(Unit: mm)

| Model | A | B | C | D | E | F | G | H | J |

|---|---|---|---|---|---|---|---|---|---|

| MHL2-10D | 38 | 36 | 51 | 26 | 56 | 76 | 100 | 24 | 80 |

| MHL2-10D1 | 54 | 52 | 67 | 42 | 78 | 118 | 142 | 39 | 108 |

| MHL2-10D2 | 72 | 70 | 85 | 60 | 96 | 156 | 180 | 57 | 146 |

*1 The J dimension is at fully closed.

*2 D1 differs from D2 when the fingers are closed because the shaft is ejected from the finger end. The J dimension differs from the value that is the G dimension with the stroke subtracted.

Precautions

- *Before using, please refer to the "Safety Precautions," the "Air Gripper Precautions," and the "Auto Switch Precautions."

- *If a workpiece is hooked onto the attachment, make sure that excessive impact will not occur at the start and the end of the movement. Failure to observe this precaution may result in shifting or dropping the workpiece, which could be dangerous.

- *See the manufacturer's catalog for information other than the above.

Teilenummer

|

|---|

| MHL2-16D-M9P |

| Teilenummer | Bezieht sich auf |

Standard-Stückpreis

| Mindestbestellmenge | Mengenrabatt | Abmessungen, wenn offen (mm) | Abmessungen, wenn geschlossen (mm) | Greifkraft (bei 0.5MPa beim Öffnen) (N) | Greifkraft (bei 0.5MPa beim Schließen) (N) | Betriebsdruckbereich (MPa) | Innendurchmesser Zylinder (mm) | Signalgeber | Anzahl der Schalter | Länge der Verbindungsleitung | Hub (mm) | Maßgeschneiderte Spezifikationen | Steckverbinder Ausführung für Greifer Öffnen/Schließen | Anschlussgewinde Ausführung | Kolben Materialien | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| - | 494.94 € | 1 | 26 Arbeitstage | 98 | 68 | 45 | 45 | 0.1~0.6 | 16 | M9P | 2 Stk. | 0.5 m | 30 | Ohne | Ohne | M | Messing |

Loading...

Grundlegende Informationen

| Ausführung | Korpus | Informationen zum Greifen | Klemme, parallele Ausführung / Offen, parallele Ausführung | Anzahl der Finger | 2 Stk. |

|---|---|---|---|---|---|

| Grundkörper, Form | Vierkant (breite) | Betriebsmethode | Doppeltwirkend | Umgebung, Anwendungen | Staubgeschützt |

| Zusätzliche Funktionen | Lagerhalterung | Hubregulierung | Nicht im Lieferumfang |

Konfigurieren

Basiseigenschaften

-

Ausführung

- MHL2-10□

- MHL2-16□

- MHL2-20□

- MHL2-25□

- MHL2-32□

- MHL2-40□

-

Abmessungen, wenn offen(mm)

-

Abmessungen, wenn geschlossen(mm)

-

Greifkraft (bei 0.5MPa beim Öffnen)(N)

-

Greifkraft (bei 0.5MPa beim Schließen)(N)

-

Innendurchmesser Zylinder(mm)

-

Signalgeber

-

Anzahl der Schalter

- 1 Stk.

- 2 Stk.

- Ohne

-

Länge der Verbindungsleitung

- 0.5 m

- 3 m

- 5 m

- Ohne

-

Hub(mm)

-

Maßgeschneiderte Spezifikationen

- ohmscher Widerstand (100 °C)

- Fett für Lebensmittelmaschinen / Fluorfett

- Fluorelastomerdichtung

- Kein Magnet

- Mit Einstellbolzen für die Breite Schließen

- Mit starker Abstreifung + Schmierretention (NBR-Dichtung)

- Ohne

- Staubbeständige Spezifikation

-

Steckverbinder Ausführung für Greifer Öffnen/Schließen

- M8 3-polig

- M8 4-polig

- M12 4-Pin

- Ohne

-

Anschlussgewinde Ausführung

- G

- M

- NPT

- Rc

-

Kolben Materialien

- Aluminiumlegierung

- Edelstahl

- Messing

-

Filtern nach CAD Format

- 2D

- 3D

Filtern nach vsl. Lieferzeit

-

- Alle Produkte

- Versand am selben Tag

- 3 Tage oder weniger

- 4 Tage oder weniger

- 26 Tage oder weniger

- 68 Tage oder weniger

- 98 Tage oder weniger

Optionale Eigenschaften

- Die Spezifikationen und Maße einiger Teile sind evtl. nicht vollständig enthalten. Genaue Details siehe Herstellerkataloge .