Willkommen im neuen MISUMI e-Katalog!

Wir haben unsere Online-Systeme aktualisiert! Erfahren Sie hier mehr!

- Zylinder-Innen-Ø: D(Ø)

- 80

- Hub: L(mm)

- 215

- Umgebung, Anwendungen

- Cushion

- Specifications

- Port thread type

- Swinging Receiving Metal

- Rod Tip Metal Fitting

- Type of Mount Support

- Rod Tip Shape

- Bellows

- Custom-made Specifications

- Ausführung

- CAD

- 2D

- 3D

- Vsl. Versanddatum

- Alle

- Innerhalb von 7 Werktagen

Pneumatik-Zylinder / CDG1, CG1 / Stirngewinde-Befestigung / doppelt wirkend / Standardkolbenstange (CG1BA80-215Z)

Achtung

- See catalog for specification details.

- Product pictures are representations. CAD data is not supported for some model numbers.

- Stückpreis (exkl. MwSt.)

- 189.32 €

- Summe (exkl. MwSt.)

- 189.32 €Preis inkl. MwSt.: 225.29 €)

- Vorausstl. Versanddauer

- 7 WerktageVorausstl. Versanddatum: 17.03.2025

| Stückzahl | 1 - 10 | 11+ |

|---|---|---|

| Stückpreis (exkl. MwSt.) (Stückpreis inkl. MwSt.) | 189.32 € (225.29 €) | 189.32 € (225.29 €) |

- * Informationen zu Lieferzeit und -kosten und Preisen

Produktdaten

Air Cylinder, Standard Type, Double Acting, Single Rod CG1 Series Specifications

Air Cylinder, Standard Type, Double Acting, Single Rod CG1 Series external appearance

Symbol Rubber bumper

Symbol Air cushion

Specifications

| Bore Size (mm) | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Action | Double acting, single rod | |||||||||

| Lubrication | Not required (non-lube) | |||||||||

| Applicable fluids | Air | |||||||||

| Proof pressure | 1.5 MPa | |||||||||

| Maximum operating pressure | 1.0 MPa | |||||||||

| Minimum operating pressure | 0.05 MPa | |||||||||

| Ambient and fluid temperature | Without auto switch: -10°C to 70°C (No freezing) With auto switch: -10°C to 60°C (No freezing) | |||||||||

| Piston speed | 50 to 1,000 mm/s | 50 to 700 mm/s | ||||||||

| Stroke length tolerance | Up to 1,000 (st 0 to +1.4) mm, up to 1,500 (st 0 to +1.8) mm | |||||||||

| Cushion | Rubber bumper, air cushion | |||||||||

| Mounting** | Basic, basic (without trunnion mounting female thread), axial foot, rod flange, head flange, rod trunnion type, head trunnion, clevis | |||||||||

| Allowable kinetic energy (J) | Rubber bumper | Rod end male thread | 0.28 | 0.41 | 0.66 | 1.20 | 2.00 | 3.40 | 5.90 | 9.90 |

| Rod end female thread | 0.11 | 0.18 | 0.29 | 0.52 | 0.91 | 1.54 | 2.71 | 4.54 | ||

| Air cushion | Rod end male thread | R: 0.35 H: 0.42 | R: 0.56 H: 0.65 | 0.91 | 1.80 | 3.40 | 4.90 | 11.80 | 16.70 | |

| Rod end female thread | 0.11 | 0.18 | 0.29 | 0.52 | 0.91 | 1.54 | 2.71 | 4.54 | ||

- *R: rod side, H: head side

- *Cylinder sizes ø80 (80‑mm diameter) and ø100 (100‑mm diameter) do not have basic (without trunnion mounting female thread), rod trunnion or head trunnion types. Foot, flange and clevis types of cylinder sizes ø20 to ø63 (20‑ to 63‑mm diameter) do not have trunnion mounting female thread. Operate the cylinder within the allowable kinetic energy.

Standard Strokes

(Unit: mm)

| Bore size | Standard strokeNote 1) | Maximum manufacturable strokeNote 2) |

|---|---|---|

| 20 | 25, 50, 75, 100, 125, 150, 200 | 201 to 1,500 |

| 25 | 25, 50, 75, 100, 125, 150, 200, 250, 300 | 301 to 1,500 |

| 32 | ||

| 40 | ||

| 50/63 | ||

| 80 | ||

| 100 |

Note 1) Intermediate strokes not listed above are produced to order.

Manufacture of intermediate strokes at 1 mm intervals is possible. (Spacers are not used.)

Note 2) The maximum manufacturable stroke shows the long stroke.

Note 3) Applicable strokes should be confirmed according to the usage. For details, refer to "Air Cylinders Model Selection" in the manufacturer's catalog.

In addition, products that exceed the standard stroke may not be able to fulfill the specifications due to deflection, etc.

Mounting Procedure

Mounting procedure for trunnion: ø20 to ø63 (20‑ to 63‑mm diameter)

Follow the procedures in the above figure when mounting a pivot bracket on the trunnion.

Mounting procedure for clevis: ø20 to ø63 (20‑ to 63‑mm diameter)

Follow the procedures in the above figure when mounting a pivot bracket on the clevis.

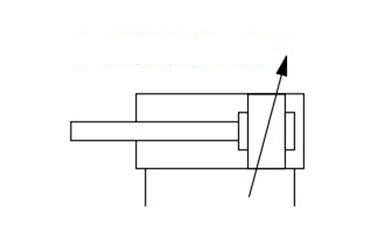

Mounting procedure for clevis: ø80 (80‑mm diameter), ø100 (100‑mm diameter)

Follow the procedures in the above figure when mounting a pivot bracket on the clevis.

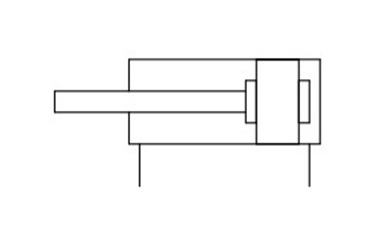

Dimensional Outline Drawing (Dimensions Other Than Those Shown Below Are the Same As the Standard Type)

(Unit: mm)

Rubber bumper dimensional outline drawing

Air cushion dimensional outline drawing

| Bore size | (E1) | *E | (F1) | *F | GA | S | TA | WA | ZZ | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rc | NPT | G | Male thread | Female thread | ||||||||

| 32 | 17 | 18 | 2 | 2 | 18 | 16.5 | 77 (85) | 17 | 22 | 119 (127) | 93 (101) | |

| 40 | 21 | 25 | 2 | 2 | 19 | 19 | 84 (93) | 18 | 23 | 136 (145) | 101 (110) | |

| 50 | 26 | 30 | 2 | 2 | 21 | 21 | 97 (109) | 20 | 25 | 157 (169) | 115 (127) | |

| 63 | 26 | 32 | 2 | 2 | 21 | 21 | 97 (109) | 20 | 25 | 157 (169) | 115 (127) | |

| 80 | 32 | 40 | 3 | 3 | 28 | 25.5 | 116 (130) | - | 32 | 190 (204) | 138 (152) | |

| 100 | 37 | 50 | 3 | 3 | 29 | 26.5 | 117 (131) | - | 33 | 119 (205) | 142 (156) | |

- *Dimensions marked with * are the same as the standard type.

- *Dimensions inside () are for long stroke.

Structural drawing

Rubber bumper structural drawing

Rubber bumper structural drawing

Component Parts

| Number | Description | Material | Note | |

|---|---|---|---|---|

| 1 | Rod cover | Aluminum alloy | Hard anodized | |

| 2 | Tube cover | Aluminum alloy | Hard anodized | |

| 3 | Piston | Aluminum alloy | - | |

| 4 | Piston rod | Stainless steel | For ø20 (20‑mm diameter), ø25 (25‑mm diameter) with built-in magnet | |

| Carbon steel* | Hard chrome plating* | |||

| 5 | Bushing | Resin/Copper alloy (Multiple layers) | - | |

| 6 | Bumper | Resin | ø32 (32‑mm diameter) or larger is common | |

| 7 | Bumper | Resin | ||

| 8 | Retaining Ring | Stainless steel | Not available for ø80 (80‑mm diameter), ø100 (100‑mm diameter) | |

| 9 | Wear ring | Resin | - | |

| 10 | Rod-end nut | Carbon steel | Zinc chromated | |

| 11 | Cushion ring A | Aluminum alloy | - | |

| 12 | Cushion ring B | Aluminum alloy | - | |

| 13 | Seal retainer | Rolled steel | Zinc chromated | |

| 14 | Cushion valve | ø40 (40‑mm diameter) or smaller | Carbon steel | Electroless nickel plating |

| ø50 (diameter 50 mm) or more | Steel wire | Zinc chromated | ||

| 15 | Cushion seal A | Urethane | ø32 (32‑mm diameter) or larger is common | |

| 16 | Cushion seal B | Urethane | ||

| 17 | Head cover | Aluminum alloy | Hard anodized | |

| 18 | Cylinder tube | Aluminum alloy | Hard anodized | |

| 19 | Rod seal | NBR | - | |

| 20 | Piston seal | NBR | - | |

| 21 | Tube gasket | NBR | - | |

| 22 | Valve seal | NBR | - | |

Note) For cylinders with auto switches, the magnet is installed in the piston.

*The material for ø20 (20‑mm diameter) and ø25 (25‑mm diameter) cylinders with auto switches is stainless steel.

*See the manufacturer's catalog for product information other than the above.

Weitere Informationen

Grundlegende Informationen

Wir freuen uns, Ihnen den überarbeiteten runden Druckluftzylinder der Serie CG1-Z mit klarerem Profil vorstellen zu können. Diese neue Serie, mit 20 bis 100 mm Kolbendurchmesser, lockt mit verbesserter Signalgeber-Montage und vielen neuen Eigenschaften, die für niedrigere Montage- und Wartungskosten sorgen und gleichzeitig mehr Flexibilität bieten. Nun können Feineinstellungen der Signalgeber nach Lockern nur einer Schraube durchgeführt werden. Außerdem wurde mit den durchsichtigen Befestigungselementen die Sichtbarkeit verbessert. Es können sowohl Kolbenstangen mit Innen- als auch mit Außengewinde gewählt werden. Mit Innengewinde wird der Zylinder bis zu 52 mm kürzer ist als die Ausführung mit Außengewinde. Der CG1-Z besticht durch vielseitige Befestigungselemente, den einfachen Aufbau und glatte Kontur. Er ist geeignet für zahlreiche Anwendungen wie Klemm- oder Pick- & Place- und Positionier-Anwendungen, in vielen Industriezweigen.

Achtung

- See catalog for specification details.

- Product pictures are representations. CAD data is not supported for some model numbers.