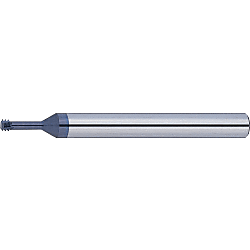

TiAlN Coated Carbide Threading Cutter, for High-Hardness Steel / for Internal Metric Threads (Teilenummern)

- Mengenrabatt

Teilenummer

Hier finden Sie die Teilenummern

zu dem gesuchten Artikel

HMINMT-M12-1.75-24

Teilenummer

|

|---|

| HMINMT-M12-1.75-24 |

| Teilenummer |

Standard-Stückpreis

| Mindestbestellmenge | Mengenrabatt | Nominal | Pitch, Number of Threads (mm) | Overall Length (L) (mm) | Maximum Processing Thread Depth (mm) | Major Diameter (φ) | Shank Diameter (φ) | Length Under Neck (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

347.87 € | 1 | Verfügbar | 7 Arbeitstage | M12 | 1.75 | 73 | 24 | 9 | 10 | 26 |

Loading...

Spezifikationen

Model Number

HMINMT

| Nominal M x P |

Maximum Machining Thread Depth |

Major Diameter D |

Overall Length L |

Length Under Neck ℓ |

Shank Diameter d |

Cutting Edge Thread No. |

No. of Grooves | |

| M2 | 0.4 | 4 | 1.55 | 58 | 4.5 | 6 | 3 | 3 |

| M2.2 | 0.45 | 4.5 | 1.65 | 58 | 5 | 6 | ||

| M2.5 | 0.45 | 5 | 1.95 | 58 | 5.5 | 6 | ||

| M2.5 | 0.45 | 7 | 1.95 | 58 | 7.5 | 6 | ||

| M3 | 0.5 | 6 | 2.35 | 58 | 6.5 | 6 | ||

| M3 | 0.5 | 9 | 2.35 | 58 | 9.5 | 6 | ||

| M3.5 | 0.6 | 7 | 2.75 | 58 | 7.5 | 6 | ||

| M4 | 0.7 | 8 | 3.1 | 58 | 9 | 6 | ||

| M4 | 0.7 | 12 | 3.1 | 58 | 12.5 | 6 | ||

| M5 | 0.8 | 10 | 3.8 | 58 | 12.5 | 6 | ||

| M5 | 0.8 | 15 | 3.8 | 58 | 16 | 6 | ||

| M6 | 1 | 12 | 4.65 | 58 | 14 | 6 | ||

| M6 | 1 | 18 | 4.65 | 58 | 20 | 6 | ||

| M8 | 1.25 | 16 | 5.95 | 58 | 18 | 6 | ||

| M8 | 1.25 | 24 | 5.95 | 58 | 24 | 6 | ||

| M10 | 1.5 | 20 | 7.8 | 64 | 23 | 8 | ||

| M12 | 1.75 | 24 | 9. | 73 | 26 | 10 | ||

[ ! ]You can use this cutter for left-handed rotation.

Take sufficient care when making the program settings.

Weitere Informationen

● The left-flute left-rotary cutting that is achieved by the original flute shape and coating allow the milling threading of high hardness steel of up to HRC62.

● Small diameter threading is possible from M2x0.4 (pilot hole diameter Ø 1.6 mm).

● The processing time is reduced since high speed cutting is possible.

● The effective thread can be cut all the way to the corners of the blind hole.

■Misumi Threading Cutter Product CNC Program Download Services

Grundlegende Informationen

Konfigurieren

Basiseigenschaften

-

Pitch, Number of Threads(mm)

-

Overall Length (L)(mm)

-

Maximum Processing Thread Depth(mm)

-

Major Diameter(φ)

-

Shank Diameter(φ)

-

Length Under Neck(mm)

-

Ausführung

- HMINMT

-

Nominal

Filtern nach vsl. Lieferzeit

-

- Alle Produkte

- 7 Tage oder weniger

Optionale Eigenschaften

- Die Spezifikationen und Maße einiger Teile sind evtl. nicht vollständig enthalten. Genaue Details siehe Herstellerkataloge .